CNC turned parts

at FESTER & ZANDER Machining Technology

At FESTER & ZANDER we offer CNC machining for complex drawing parts as individual parts or also in smaller series. Thanks to our many years of experience, we also work for our long-standing customers in the food industry, automotive, mechanical and plant engineering sectors.

FIRST CLASS CNC TURNED PARTS

We offer CNC turning services for components with a diameter of 5 mm to 800 mm and a maximum component length of 2,500 mm. However, if your dimensions exceed these, please feel free to send us an enquiry – thanks to our drilling and milling capabilities, there are hardly any limits to our flexibility!

Emco MAXXTURN 110

Swing diameter max.: 840 mm

Swing diameter over face guide: 550 mm

Longitudinal travel Z: 2,500 mm

Voest Alpin WNC 700 S

Swing diameter max.: 750 mm

Swing diameter over face guide: 610 mm

Longitudinal travel Z: 3,000 mm

CTX 520 linear

Swing diameter max.: 680 mm

Swing over face guide: 565 mm

Longitudinal travel Z: 1,350 mm

In addition to CNC turning, we also provide CNC milling services. For this we use CNC machines from the company DMG.

DMG DMF 360 linear

5 -axis machine

Working area 3,600 x 1,100 x 900 mm

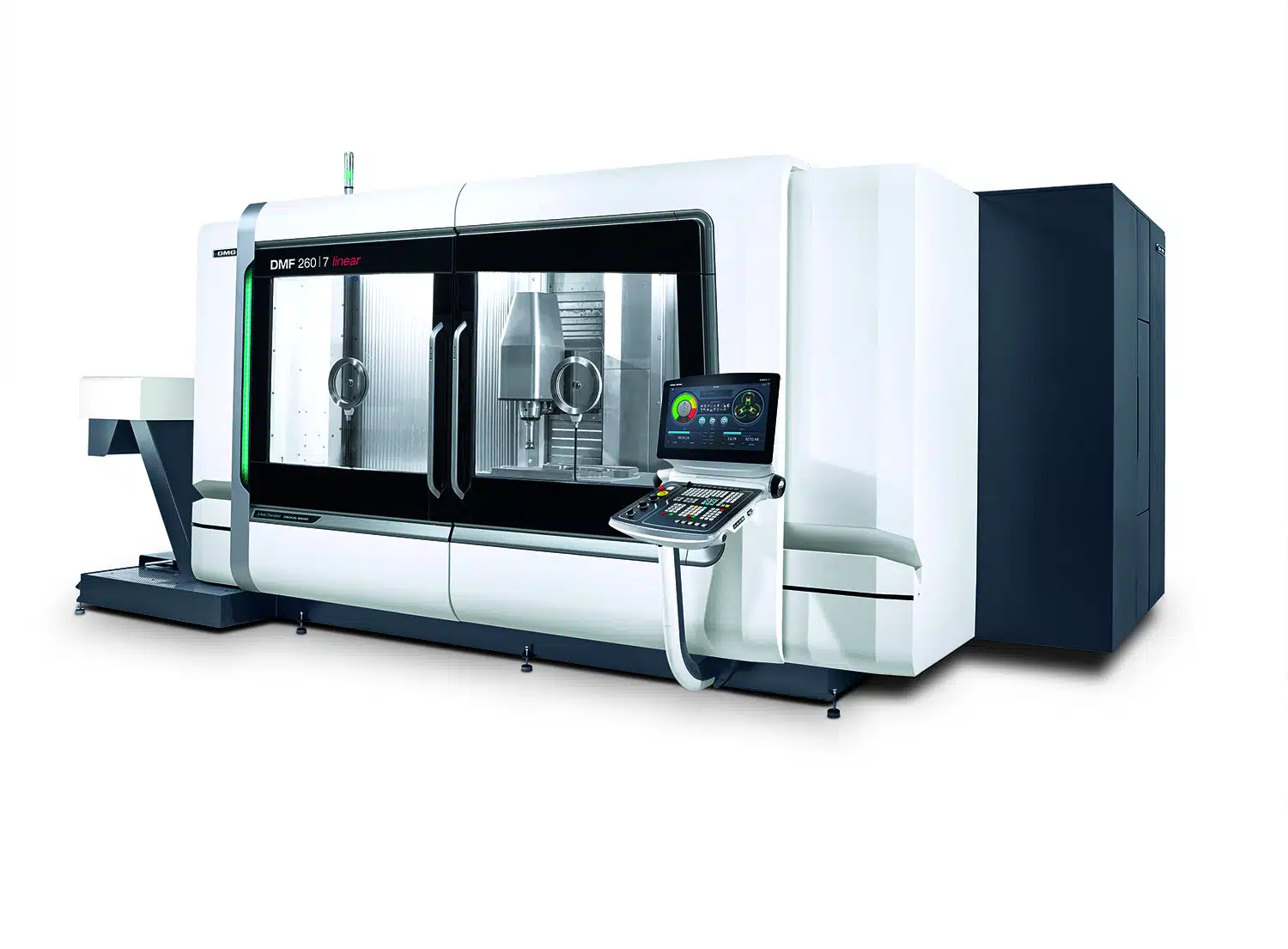

DMG DMF 260 linear

5 -axis machine

Working area 2,600 x 1,100 x 900 mm

DMG DMF 180 linear

5 -axis machine

Working area 1,800 x 1,100 x 900 mm

DMG DMU 50 3rd Gen

5 -axis machine

Working area: 650 x 520 x 475 mm

DMG DMC 1450 V

Working area: 1,450 x 700 x 550 mm

DMG DMC 835

Working space: 835 x 510 x 510 mm

Automation for series milled parts

Discover advanced serial milled part machining with our state-of-the-art CNC milling machines!

Our specialised service offers you customised machining solutions according to your individual specifications. With our proven automation technology and experienced team, we can efficiently and precisely machine your components weighing up to 15 kg and with a maximum size of 120×120 mm – around the clock!

Whether it’s small or medium series, we are your reliable partner for all types of series milled parts. Our experts are at your side to meet your requirements and deliver first-class results.

Our goal is to provide you with an optimised manufacturing solution and increase your productivity. With our innovative CNC technology and expertise, we can help you achieve your goals and increase the success of your business.

Opt for first-class serial milled part machining and rely on our professional service. Contact us today to learn more about our services and how we can help you successfully implement your projects.

Ask us without obligation!

START REQUEST NOWOUR REFERENCES

HOW TO FIND US

CNC TURNED PARTS - WE ARE YOUR PARTNER!

In our second-generation family business, we take care of everything from the design to the manufacture of your drawing parts. Regardless of whether it is a matter of tools or devices, at Fester & Zander Zerspannungstechnik you receive all work steps from a single source. We are always available to answer your questions personally and look forward to hearing from you. You can come to us with any suggestion – we will work with you to find a solution and put together an individual offer to suit you. We are looking forward to your wishes and would like to make every turning part the best for you!

"*" indicates required fields

CNC-TURNED PARTS: FREQUENTLY ASKED QUESTIONS

What are CNC turned parts?

CNC turned parts are produced on a CNC lathe in conjunction with translatory movements of the tools. A rotary movement of the tool serves as the motor of the process.

How does a CNC lathe work?

The CNC lathe is a specific type of lathe. With it, tool movements are controlled by numerically stored programmes and the work processes are automated.

What are precision turned parts?

Precision turned parts are certain tools which are made of metal, non-ferrous metal, special materials or plastic. The parts are manufactured by turning on a lathe or a turning machine.

What does CNC turning mean?

CNC turning is an automated manufacturing process that is used to produce rotationally symmetrical components. It is mainly used in the metalworking industry and has several advantages over the conventional lathe process in terms of speed, automation and processing.

WHAT EXACTLY ARE CNC TURNED PARTS?

Die CNC-Drehteile werden auf einer CNC-Drehmaschine in Verbindung mit translatorischen Bewegungen der Werkzeuge hergestellt. Eine Drehbewegung des Werkzeugs dient dabei als Motor des Vorgangs. Der Vorgang des CNC-Drehens erzielt einen hohen Materialabtrag und erweist sich dadurch auch als sehr kosteneffizient.

Die Bauteile des CNC-Drehens können aus Stahl, Edelstahl, Titan, Aluminium und Kunststoffen bestehen und mit hochpräzisen CNC-Drehmaschinen sowohl als Serienbauteilen in kleiner und großer Stückzahl – und auch als einzelne Prototypen angefertigt werden.

Das CNC-Drehverfahren gilt als computergestützte Fertigungstechnologie bei dem ein massives Werkstück rotiert wird, während fixierte Schneidwerkzeuge das Material von diesem einen Werkstück abtragen und es so dann in eine endgültige Form bringen.

THIS IS HOW THE PRODUCTION OF CNC TURNED PARTS WORKS

We process all materials on request. We serve you with our batch sizes, which can be either single part or prototype production or small to medium series. Thanks to our flexibility through combinable drilling and milling, we can guarantee you fast, clean and efficient work.

CNC stands for “Computerised Numerical Control”. This specific type of turning describes a control technique which is used in modern industrial machining centres. This type of CNC work is used for the automatic production of complex components.

The following points are important to note when manufacturing CNC turned parts:

- The tool in CNC turning is in continuous engagement and not subject to interrupted cutting conditions.

- CNC machines are simply built, but have strong performance and are less expensive in dimensions than, for example, milling machines.

- In CNC machining, the pure lathes can be used with combined machines that have driven tools and milling spindles.

- The combination of these turning-milling machines makes complete machining of workpieces and turned parts possible in one clamping.

Whether special screws, model components or door handles – with our CNC machining, we at Fester & Zander can produce any piece to within a fraction of a millimetre. With our CNC machines, it is possible for us to automate the loading, the tool change, the monitoring and also the quality control during the entire production process in our modern machining centre.