Fester & Zander Zerspanungstechnik GmbH

High-precision CNC milled and turned parts.

Your reliable partner for quality!

Welcome to Fester & Zander Zerspanungstechnik GmbH!

Your full-service partner for turning and milling.

Our company was created in 2021 through the merger of two renowned companies: CFK-Leipzig GmbH (fixture and tool construction, founded in 2010) and Zander Industrietechnik und Service GmbH (contract manufacturing, founded in 1997). This merger enabled us to bundle our expertise to offer you a comprehensive solution from design to manufacture and assembly of your drawing parts, fixtures or tools from a single source.

For more than a decade, we have been a proud system supplier for well-known manufacturers in extrusion technology as well as for the aerospace industry. Our focus is on CNC machining, where we produce complex drawing parts efficiently and precisely in contract manufacturing – be it individual parts, small series or medium series. With a wide range of machining options, including turning, milling, grinding and welding, we offer complete machining of your parts.

Thanks to our many years of experience in the food industry, automotive industry and mechanical and plant engineering sectors, we understand the specific requirements and in many cases act as a reliable “extended workbench” for our customers.

We are proud to offer you high-quality and customised solutions and look forward to mastering your machining challenges.

Your team from Fester & Zander Zerspanungstechnik GmbH

We are certified

Services

Always on the pulse of our customers.

Contract manufacturing

- Milling

(5-axis simultaneous machining) - Turning

- Welding

- Grinding

- Sawing

Toolmaking / Mechanical engineering

- Assembly/testing devices

- Fibre composite and autoclave tools

- Foaming tools

- Deep-drawing tools

Engineering service

- CAD design CATIA V5

- CAM programming Hypermill

- Measuring Faro measuring arm system

References

Unlimited machining possibilities.

Ask us without obligation!

START REQUEST NOWCNC MILLING

Our claim: highest quality.

Are you looking for an experienced partner for CNC milling, including 5-axis machining? Precision, quality and speed are our focus – regardless of size, complexity or material. We offer prompt quotations and speedy production of your CNC milled parts, without compromising on quality or efficiency. Attractive prices and transparent communication throughout the entire process are a matter of course for us.

- Maximum machining up to 3,600mm x 1,200mm x 1,100mm

- 5-axis simultaneous machining up to 750mm x 750mm x 500mm

- All machines of the company DMG

- Batch sizes: Single part or prototype production, small to medium series

- Materials: steel, stainless steel, aluminium, brass, copper, plastic

DMG DMF 360 linear

5 -axis machine

Working area 3,600 x 1,100 x 900 mm

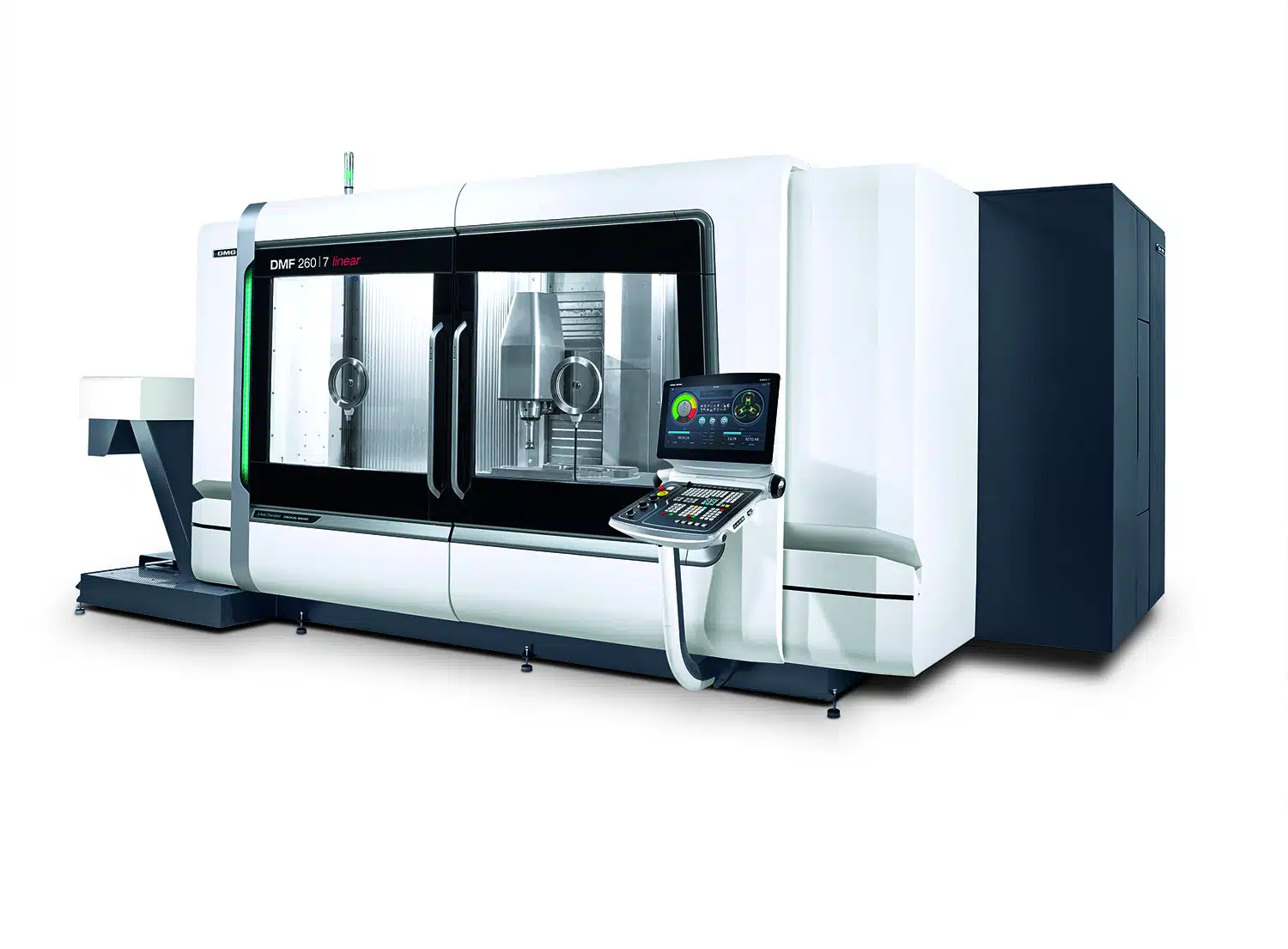

DMG DMF 260 linear

5 -axis machine

Working area 2,600 x 1,100 x 900 mm

DMG DMF 180 linear

5 -axis machine

Working area 1,800 x 1,100 x 900 mm

DMG DMU 50 3rd Gen

5 -axis machine

Working area: 650 x 520 x 475 mm

DMG DMC 1450 V

Working area: 1,450 x 700 x 550 mm

DMG DMC 835

Working space: 835 x 510 x 510 mm

CNC turning

Fast and efficient.

Are you looking for a new supplier in the field of CNC turning for high-precision turned parts? We offer optimal quality and flexibility, regardless of the material, workpiece size, complexity or number of manufactured parts. Fast quotations and short delivery times are a matter of course for us. As a procurement manager, you certainly also have an eye on costs – with us you will find the ideal balance between quality and price.

- Maximum component diameter from 10 to 700mm (dimensions exceeding this on request)

- Maximum component length: 2,500 mm (exceeding dimension on request)

- Flexibility through combinable drilling and milling operations

- Batch sizes: Single part or prototype production, small to medium series

- Materials: steel, stainless steel, aluminium, brass, copper, plastic

Emco MAXXTURN 110

Swing diameter max.: 840 mm

Swing diameter over face guide: 550 mm

Longitudinal travel Z: 2,500 mm

Voest Alpin WNC 700 S

Swing diameter max.: 750 mm

Swing diameter over face guide: 610 mm

Longitudinal travel Z: 3,000 mm

CTX 520 linear

Swing diameter max.: 680 mm

Swing over face guide: 565 mm

Longitudinal travel Z: 1,350 mm

Automation for series milled parts

Manless through the night.

Discover advanced serial milled part machining with our state-of-the-art CNC milling machines!

Our specialised service offers you customised machining solutions according to your individual specifications. With our proven automation technology and experienced team, we can efficiently and precisely machine your components weighing up to 15 kg and with a maximum size of 120×120 mm – around the clock!

Whether it’s small or medium series, we are your reliable partner for all types of series milled parts. Our experts are at your side to meet your requirements and deliver first-class results.

Our goal is to provide you with an optimised manufacturing solution and increase your productivity. With our innovative CNC technology and expertise, we can help you achieve your goals and increase the success of your business.

Opt for first-class serial milled part machining and rely on our professional service. Contact us today to learn more about our services and how we can help you successfully implement your projects.

PALLET HANDLING

We invest - you earn.

Our new DMG DMU 50 with PH Cell pallet handling allows automated loading and unloading of the machine for higher efficiency. With a maximum capacity of 24 pallets and up to 22 hours per day (unmanned), up to 400x400mm components weighing up to 300 kg can be processed. The minimum batch size is 4 pieces. Contact us and we will work together for your success!

Our brand new DMG DMU 50 and PH Cell pallet handling allows automated loading and unloading for maximum efficiency in your production. With an impressive capacity of up to 24 pallets and up to 22 hours per day (fully automated), components up to 400×400 mm in size and weighing up to 300 kg can be precisely machined. The minimum batch size is 4 pieces, so we can also offer the right solution for your individual requirements.

Contact us and benefit from the advantages of our modern technology. Let us successfully implement your projects together.

Ask us without obligation!

START REQUEST NOWGrinding

Precision until the last micrometre.

Our modern milling and turning machines enable us to machine your components with high precision. However, if you have parts with very tight dimensional tolerances and low roughness that our machines cannot achieve, our surface grinding machines are ready and waiting.

Our experienced team ensures that all tolerances and surface roughness are precisely maintained to give you the best possible quality.

With process paths up to 1.000×500 mm and a maximum component height of 350 mm, we can precisely grind almost any part and meet your requirements.

Rely on our expertise and experience to successfully realise your demanding projects. Contact us and let us convince you of our first-class service!

Fairs

So that nothing can go wrong in your assembly.

Our quality assurance on our measuring machines is a crucial step in our production process. Precision and accuracy are our top priorities and our highly skilled technicians regularly calibrate and adjust our measuring machines to ensure they are always up to date and provide accurate measurements.

We have state-of-the-art measuring equipment, including a Mitutoyo coordinate measuring machine and a FARO measuring arm, which enable us to inspect your products with the highest accuracy. By using tactile and non-contact measurement techniques, we can accurately analyse the relevant characteristics and dimensions of your parts.

Our experts do their utmost to detect deviations immediately and correct possible errors at an early stage to ensure the consistently high quality of your parts. With great care and precision, we monitor the entire manufacturing process and ensure that your requirements and specifications are fully met.

Rely on our comprehensive quality assurance, supported by state-of-the-art measuring equipment, to ensure the outstanding precision and quality of your products. Contact us and discover how we can support your projects with the highest reliability and accuracy.

Saw cut

Your expert for precise saw cuts.

Our production facility is equipped with the state-of-the-art, fully automatic Wagner 2-column band saw. With this technology, we cut series parts made of steel, plastic and non-ferrous metal with profiles of up to 420x420mm to the precise dimensions required for further machining.

Do you only need the cutting to size? We also offer you this service. Send us your materials and dimensions and we will take care of it.

HOW TO FIND US

CAREER

Join our team - We are looking for reinforcement!

We invite you to become part of our established company and support us in exciting projects for diverse industrial customers.

Enrich our team with your energy and expertise. Apply now and shape the future of industrial projects with us. We look forward to getting to know you!

Contact form

"*" indicates required fields