CNC MILLING

made easy with us!

At FESTER & ZANDER we offer CNC machining for complex drawing parts as individual parts or also in smaller series. Thanks to our many years of experience, we also work for our long-standing customers in the food industry, automotive, mechanical and plant engineering sectors.

FIRST CLASS RESULTS FROM THE CNC MILLING MACHINE

With our CNC machines from DMG, we are happy to machine all your materials on request. We can serve you in milling with a component dimension of 3,600 mm x 1,100 mm x 600 mm and 5-axis simultaneous machining.

DMG DMF 360 linear

5 -axis machine

Working area 3,600 x 1,100 x 900 mm

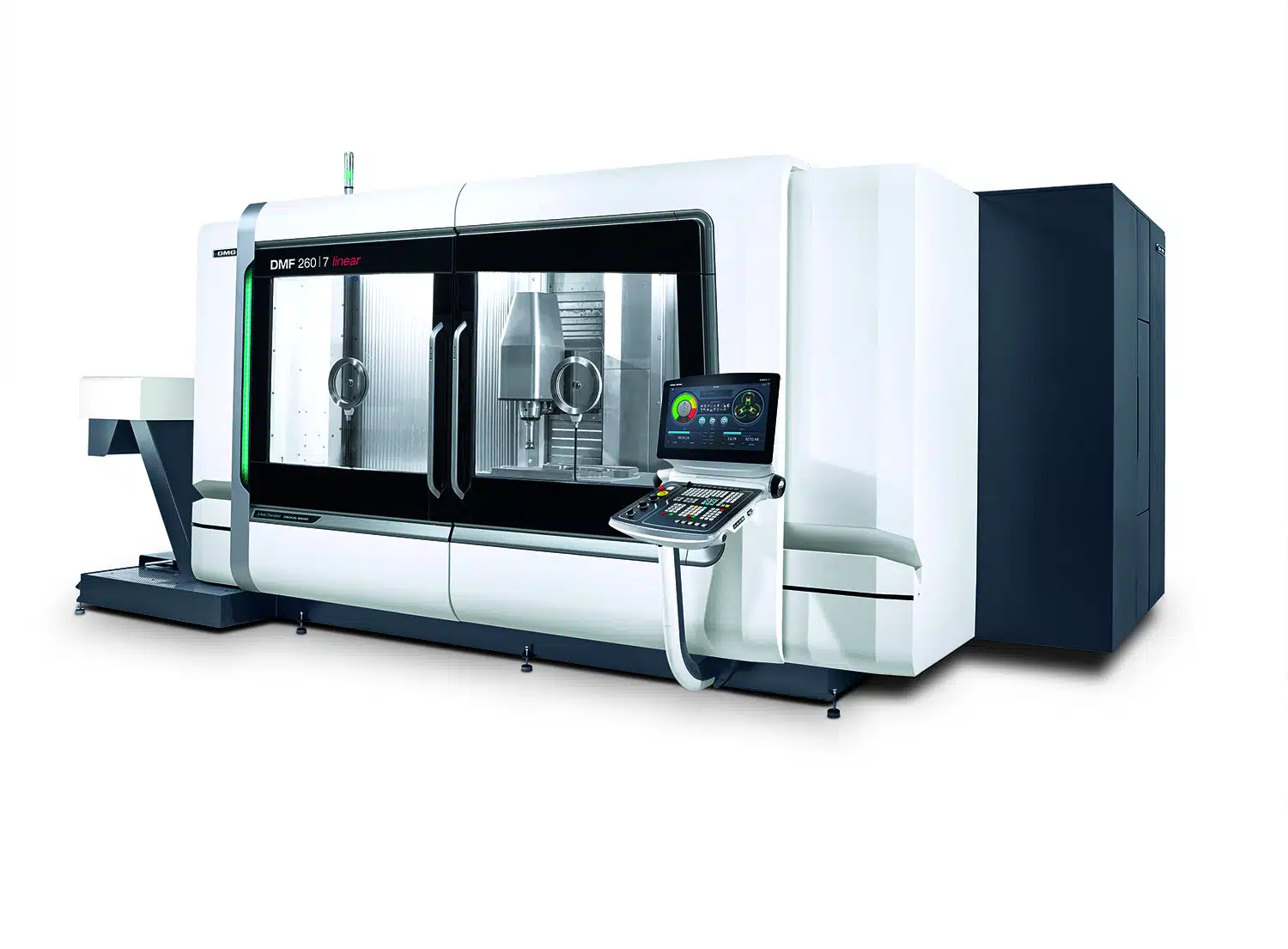

DMG DMF 260 linear

5 -axis machine

Working area 2,600 x 1,100 x 900 mm

DMG DMF 180 linear

5 -axis machine

Working area 1,800 x 1,100 x 900 mm

DMG DMU 50 3rd Gen

5 -axis machine

Working area: 650 x 520 x 475 mm

DMG DMC 1450 V

Working area: 1,450 x 700 x 550 mm

DMG DMC 835

Working space: 835 x 510 x 510 mm

In addition to CNC milling, we also offer CNC turning with a component diameter of 5 mm to 800 mm and a maximum component length of 2,500 mm. However, if your dimensions exceed this, please feel free to send us an enquiry about this, because thanks to our drilling and milling machining, there are hardly any limits to our flexibility!

Emco MAXXTURN 110

Swing diameter max.: 840 mm

Swing diameter over face guide: 550 mm

Longitudinal travel Z: 2,500 mm

Voest Alpin WNC 700 S

Swing diameter max.: 750 mm

Swing diameter over face guide: 610 mm

Longitudinal travel Z: 3,000 mm

CTX 520 linear

Swing diameter max.: 680 mm

Swing over face guide: 565 mm

Longitudinal travel Z: 1,350 mm

Automation for series milled parts

Manless through the night.

Discover advanced serial milled part machining with our state-of-the-art CNC milling machines!

Our specialised service offers you customised machining solutions according to your individual specifications. With our proven automation technology and experienced team, we can efficiently and precisely machine your components weighing up to 15 kg and with a maximum size of 120×120 mm – around the clock!

Whether it’s small or medium series, we are your reliable partner for all types of series milled parts. Our experts are at your side to meet your requirements and deliver first-class results.

Our goal is to provide you with an optimised manufacturing solution and increase your productivity. With our innovative CNC technology and expertise, we can help you achieve your goals and increase the success of your business.

Opt for first-class serial milled part machining and rely on our professional service. Contact us today to learn more about our services and how we can help you successfully implement your projects.

Ask us without obligation!

START REQUEST NOWReferences

Unlimited machining possibilities.

HOW TO FIND US

CNC MILLING - WE ARE YOUR PARTNER!

We are always personally available for any queries and look forward to hearing from you. You can come to us with any suggestion – we will work with you to find a solution and put together an individual offer that suits you. We look forward to it!

"*" indicates required fields

CNC MILLING:

FREQUENTLY ASKED QUESTIONS

Which CNC milling machines are available?

There are many different CNC milling machines from different suppliers, which differ in their designs and areas of application, as well as in the number of axes. In our sales department, we use all milling machines from DMG.

What does CNC milling mean?

CNC milling is described as a high-precision machining process based on “Computerised Numerical Control” – i.e. computer-assisted and freely programmable machine control.

How does CNC milling work?

The process of CNC milling is controlled by a microcomputer, which is located in the control section of the machine tool. This makes it possible to work with a precision that cannot be achieved with manual production.

How much does a CNC milling operator earn?

As a CNC milling operator, you earn an average gross salary of around €2,200 to €2,800 for 40 hours per week.

WHAT EXACTLY DOES CNC MILLING MEAN?

CNC milling is described as a high-precision machining process based on computerised numerical control, i.e. computer-assisted and freely programmable machine control. It is a popular machining process in the automotive and aerospace industries.

The process of CNC milling is controlled by a microcomputer, which is located in the control section of the machine tool. This makes it possible to work with a precision that cannot be achieved with manual production. Parts can be produced in both small and large quantities.

THE ADVANTAGES OF CNC MILLING

In CNC milling, the whole tool moves. First of all, a programme is created based on the geometric representation of the finished workpiece. The special features of this process can be well illustrated by the advantages of CNC milling:

Modern plants

Ability to clamp any tool quickly and precisely

High flexibility, speed and efficiency

Shortening the process chain

Minimised time and costs

Exact determination of the tool position

Almost any material can be milled on five axes

Even complicated parts can be easily realised

Absolute precision, not comparable with conventional milling processes